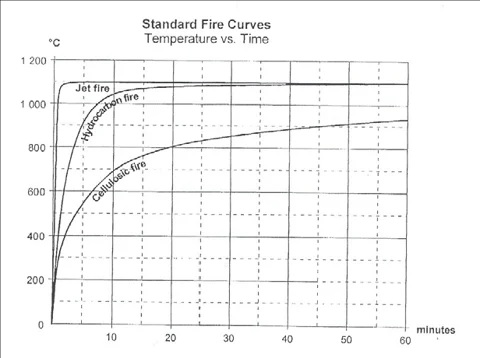

Jet fires are expelled from an orifice, e.g. leak in pipe or vessel, under pressures of 2 bar or greater. They are the most severe fire scenario, considering the effect of erosion of steel and also the significantly higher rate of burning due to turbulent fuel/air mixing. Typical radiation value after 5 minutes is 320 kW/m2.

In conclusion, jet fire outbreak is the worst scenario possible. Fire protection systems which are to withstand one of the two, or both, types of fires therefore need to be adequately engineered and manufactured in order to provide safety.

Rules and regulations

Up to date, there are no internationally recognized hydrocarbon fire test standards. Used standards for hydrocarbon fire test are e.g. the UK Department of Energy Hydrocarbon Time/Temperature Relationship and IMO Resolution MSC.307(88) Performance Criteria.

“H” class divisions have to be insulated with non-combustible or equivalent materials such that the unexposed side will not rise more than 140°C above the original temperature, nor will the temperature at any one point, including any joint, rise more than 180°C above the original temperature, within the time listed below:

H120 - 120 minutes

H60 - 60 minutes

H0 - 0 minutes

Unlike the hydrocarbon fire test standard, there are internationally recognized jet fire test standards, like the OTI 95634 Jet fire resistance test of passive fire protection materials, and the ISO 22899-1 Determination of the resistance to Jet Fires of passive fire protection materials. These are however not as elaborate and comprehensive as the IMO FTP code, leaving the need for additional specification of both the jet fire characteristics and the required performance of the fire protection materials. Common jet fire ratings are:

J120 - 120 minutes

J60 - 60 minutes

J0 - 0 minutes

Fire and blast protective products which need to withstand hydrocarbon fires or jet fires have to be rated accordingly in order to maintain safety for people and the whole structure.